Introduction:

Standard Pallet Racking, also known as Selective Pallet Racking or Heavy-Duty Beam Racking, is the most classic and versatile storage solution in warehouse systems. It employs a simple modular structure of “upright frames + beams,” providing an independent storage location for each palletized goods and achieving 100% goods accessibility. This design ensures that forklifts can reach any storage location without obstruction for storage and retrieval operations, combining high space utilization with exceptional operational efficiency. It serves as the foundational equipment for enhancing storage capacity in various types of warehouses.

Key Features of Standard Pallet Racking:

- 100% Goods Accessibility: As a “selective” racking system, each pallet can be directly and independently accessed without moving other goods, making it particularly suitable for warehouses with a wide variety of products and small batch sizes.

- Simple Structure, Durable and Robust: Features a proven connection structure between upright frames and beams with strong load-bearing capacity, ensuring safety and reliability. Manufactured from high-quality steel for long-lasting durability.

- High Space Utilization: Effectively converts vertical warehouse space into storage capacity through optimized design, reducing aisle space and maximizing storage density.

- Full Pallet Storage, Clear Visibility: Palletized goods are stored intact, facilitating easy counting, management, and inventory strategies such as FIFO (First-In, First-Out) or FILO (First-In, Last-Out).

- Flexibility and Scalability: The modular design allows for easy installation, adjustment, and expansion. Beam heights can be adjusted as needed to accommodate goods of different sizes, and future layout changes are straightforward.

Racking System Layout:

Specifications:

(The following are general specification ranges. Specific designs require professional planning based on actual load capacity, dimensions, and warehouse conditions.)

| Item | Specification |

|---|---|

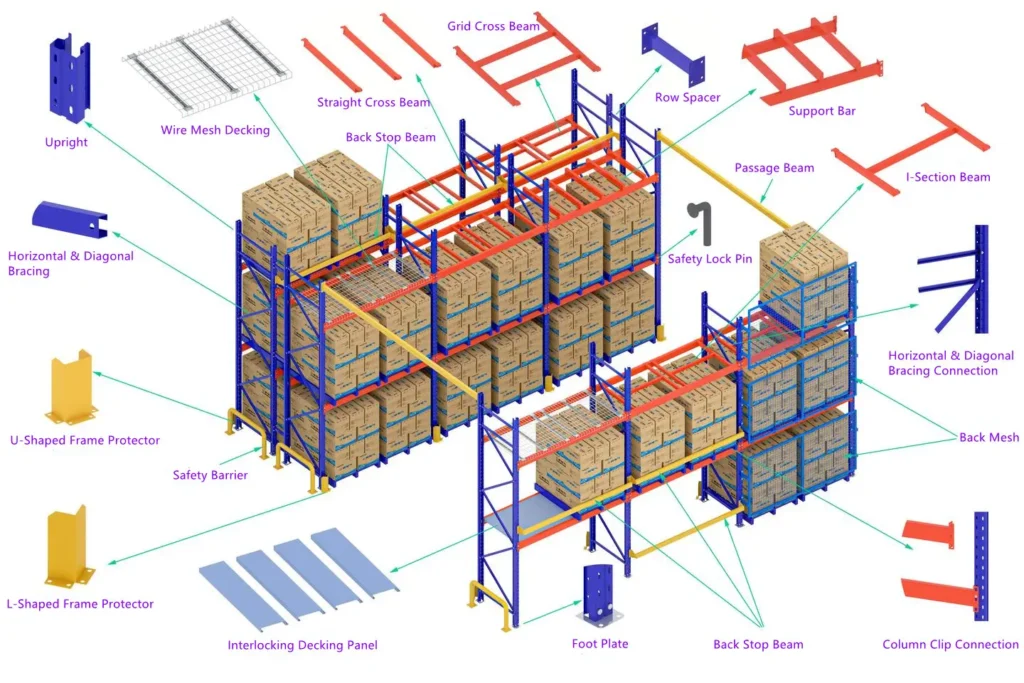

| Structural Composition | Upright frames, beams, cross beams/decking (optional), safety locks, foot guards, etc. |

| Load Capacity | Beam span determines load per level. Typical range: 1,000kg – 3,000kg/level. Custom higher capacities available. |

| Racking Height | Typically ≤12 meters, depending on warehouse clear height and forklift lifting capability. |

| Upright Specification | High-quality rolled profiles (e.g., 80x60mm, 90x70mm, 100x70mm). Size selected based on load and height requirements. |

| Beam Specification | Various beam profiles (P-shaped beams, box beams) selected according to span and load requirements. |

| Level Adjustment | Mechanical locking connection to uprights. Adjustable at 75mm/50mm increments for flexible height adaptation. |

| Aisle Requirements | Requires counterbalance forklifts or reach trucks. Typical aisle width: 2.8-3.5 meters. |

| Surface Treatment | Epoxy electrostatic spraying after pickling and phosphating. Provides rust prevention, corrosion resistance and clean appearance. |